Ipayipi lensimbi liwumugqa omude wensimbi ongenalutho, osetshenziswa kabanzi njengepayipi lokuthutha uketshezi, njengowoyela, igesi yemvelo, amanzi, igesi, umusi, njll. Ngaphezu kwalokho, lilula ngesisindo uma ligoba futhi linamandla okugoqa. okufanayo, ngakho-ke ibuye isetshenziswe kabanzi Isetshenziselwa ukwenziwa kwezingxenye zemishini kanye nezakhiwo zobunjiniyela.Ibuye isetshenziselwe ukukhiqiza izikhali ezejwayelekile ezehlukene, imiphongolo, amagobolondo, njll. Amapayipi ensimbi ashiselwe, aziwa nangokuthi amapayipi ashiselwe, angawamapayipi ensimbi athungelwe, okungamapayipi ensimbi enziwe ngamapuleti ensimbi noma amapheshana ngemva kokuphonswa nokushisela, ngokuvamile ngensimbi. ubude bamamitha angu-6.Inqubo yokukhiqiza ipayipi yensimbi ehlanganisiwe ilula, ukusebenza kahle kokukhiqiza kuphezulu, kunezinhlobonhlobo eziningi kanye nokucaciswa, futhi ukutshalwa kwezimali kwemishini kuncane, kodwa amandla ajwayelekile aphansi kunepayipi lensimbi engenamthungo.

Ukuhlukaniswa kwamapayipi ensimbi ashiselwe

Kuhlukaniswa ngendlela yokukhiqiza

(1) Ngokwenqubo - ipayipi elishiselwe i-arc, ipayipi elishiselwe ukumelana (imvamisa ephezulu, imvamisa ephansi), ipayipi elishiselwe igesi, ipayipi elishiselwe esithandweni somlilo

(2) Ngokusho kwe-weld - ipayipi elihlanganisiwe eliqondile, ipayipi elihlanganisiwe elivunguzayo

Kuhlukaniswa ngomumo wesigaba

(1) Amapayipi ensimbi alula anesigaba esiphambanayo—amapayipi ensimbi ayindilinga, amapayipi ensimbi ayizikwele, amapayipi ensimbi ayi-oval, amapayipi ensimbi angonxantathu, amapayipi ensimbi anezinhlangothi ezine, amapayipi ensimbi e-rhombus, amapayipi ensimbi ane-octagonal, iziyingi zensimbi eziyisiyingi, nokunye.

(2) Amapayipi ensimbi ayingxenye eyinkimbinkimbi – amapayipi ensimbi ayi-hexagonal angalingani, amapayipi ensimbi anamacembe amahlanu amise okweplalamu, amapayipi ensimbi ayi-convex kabili, amapayipi ensimbi amise okwemelon, amapayipi ensimbi amise okwekhabe, amapayipi ensimbi ayikhonikhi, amapayipi kathayela; amapayipi ensimbi yecala, njll.

Ngokusho kobukhulu bodonga, ingahlukaniswa: ipayipi lensimbi elinezindonga ezincane kanye nepayipi yensimbi enodonga obukhulu;

Ngokusho kokuma kokuphela, ingahlukaniswa: ipayipi elihlanganisiwe eliyindilinga kanye ne-special-shaped (isikwele, flat, njll) ipayipi ehlanganisiwe;

Ukuhlukaniswa ngenhloso

Ipayipi elishiselwe okuvamile, ipayipi elishiselwe uthango, ipayipi elishiselwe umoya-mpilo, isikhwama sentambo, ipayipi elishiselwe i-metric, ipayipi le-idler, ipayipi lepompo elijulile, ipayipi lemoto, ipayipi le-transformer, ipayipi elishiselwe ngogesi elinezindonga ezincanyana, ipayipi likagesi elishiselwe okukhethekile, isikafula ipayipi kanye nepayipi elihlanganisiwe elivunguzayo.

Inhloso eyinhloko

Isetshenziswa kabanzi kwezobunjiniyela bokuhlinzekwa kwamanzi, imboni ye-petrochemical, imboni yamakhemikhali, imboni yamandla kagesi, ukuchelela ngenkasa kwezolimo, kanye nokwakhiwa kwamadolobha.Ungomunye wemikhiqizo engamashumi amabili esemqoka ethuthukiswe izwe lethu.

Isetshenziselwa ukuthuthwa kwamanzi: ukuhlinzekwa kwamanzi kanye nokukhipha amanzi.Ezokuthutha ngegesi: igesi, umusi, igesi ye-petroleum ewuketshezi.

Ngezinhloso zesakhiwo: njengamapayipi okunqwabelanisa, njengamabhuloho;amapayipi amachweba, imigwaqo, izakhiwo zokwakha, njll.

Amapayipi ensimbi ashiselwe ahlukaniswe ama-galvanized futhi angenayo i-galvanized ngokusho kokwelashwa okungaphezulu kwepayipi.Amapayipi ensimbi ashiselwe angahlukaniswa abe yizinhlobo ezimbili lapho ephuma efektri: enye ifakwe ekugcineni kwepayipi, kanti enye ayifakwanga ekugcineni kwepayipi.Emapayipini ensimbi ashiselwe anemicu emaphethelweni epayipi, ubude bepayipi ngalinye buyi-4-9m, futhi kumapayipi ensimbi ahlanganisiwe ngaphandle kwezintambo, ubude bepayipi ngalinye buyi-4-12m.

Amapayipi ensimbi ashiselwe ahlukaniswe amapayipi ensimbi anezindonga ezincane, amapayipi ensimbi agqinsile kanye namapayipi ensimbi ajwayelekile ngokusho kobukhulu bodonga lwamapayipi.Amapayipi ensimbi ajwayelekile yiwona asetshenziswa kakhulu kumapayipi enqubo, futhi ukucindezela kwawo kokuhlola kungu-2.0MPa.Ingcindezi yokuhlola yepayipi lensimbi elijiyile ingu-3.0MPa.

Kunezindlela eziningi zokuxhuma zamapayipi ensimbi ashiselwe, okuhlanganisa ukuxhuma okufakwe intambo, uxhumano lwe-flange kanye nokushisela.Uxhumano lwe-flange luhlukaniswe ngoxhumano lwe-flange oluhlanganisiwe kanye nokuxhumeka kwe-welding flange, futhi indlela yokufaka i-welding ihlukaniswe nge-welding yegesi kanye ne-arc welding.

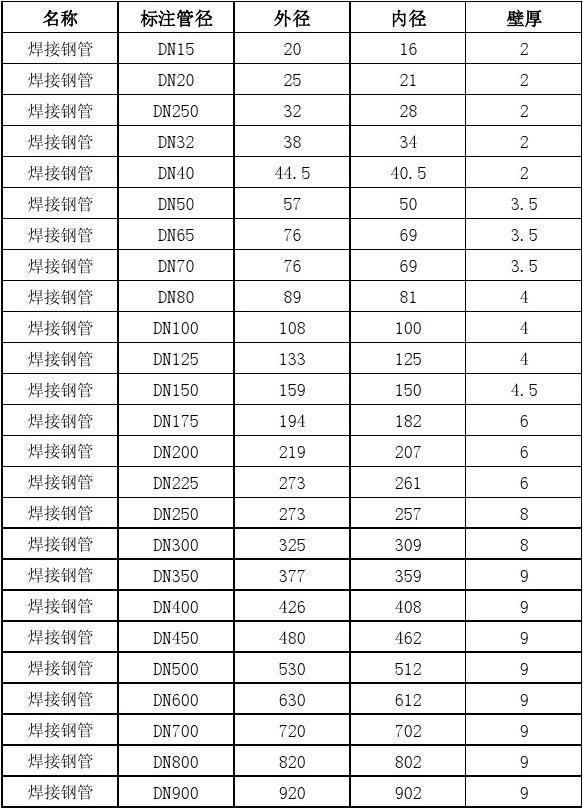

Okuvame ukusetshenziswa ashiselwe steel ipayipi incazelo ububanzi: okuzisholo ububanzi 6 ~ 150mm

Amapayipi ensimbi ashiselwe angahlukaniswa izigaba ezintathu ngokuya ngenqubo yokwenza:

1. Ukumelana nogesi okushiselwe ipayipi lensimbi

Ukumelana nogesi okushiselwe ipayipi lensimbi, igama lesiNgisi elithi ERW (Ipayipi elishiselwe ukumelana nogesi), uhlobo lwe-weld luwumthungo oqondile.I-resistance welding ithatha indlela ye-pressure welding ngaphandle kwe-filler metal.Akukho ukugcwaliswa kwezinye izingxenye ku-weld seam.Umphumela wesikhumba kanye nomphumela oseduze we-high-frequency current yenza umkhawulo wepuleti ushise ngokushesha ekushiseni kwe-welding, futhi ukubunjwa kwakhiwa ngokucindezela i-roller extrusion.Izicubu ziyashisela.

Ukumelana ashiselwe ipayipi yensimbi ingahlukaniswa izigaba ezimbili: high frequency ukumelana Welding HFW (High frequency ashiselwe ipayipi) kanye low frequency ukumelana Welding LFW (Low imvamisa Welding).

Amapayipi ensimbi e-ERW asetshenziselwa ikakhulukazi ukuthutha umhwamuko nezinto eziwuketshezi ezifana nowoyela negesi yemvelo, futhi angahlangabezana nezidingo ezihlukahlukene zokucindezela okuphezulu nokuphansi.Njengamanje, banesikhundla esibalulekile emkhakheni wamapayipi okuthutha emhlabeni.

2. Ipayipi lensimbi elivunguzayo

Ipayipi lensimbi elishiselwe ku-Spiral, igama lesiNgisi elithi SSAW (Ipayipi le-Spiral submerged-arc welding), uhlobo lwe-weld luyi-spiral seam.Indlela ye-arc welding engaphansi kwamanzi iyamukelwa, futhi izingqimba eziphindwe kabili zangaphakathi nangaphandle ziyashiswa.I-arc welding engaphansi kwamanzi (okuhlanganisa i-arc surfacing engaphansi kwamanzi kanye ne-electroslag Surfacing, njll.) iyindlela ebalulekile yokushisela, enezinzuzo zekhwalithi yokushisela ezinzile, ukukhiqiza okuphezulu kwe-welding, akukho ukukhanya kwe-arc kanye nentuthu encane nothuli.

Ipayipi elishiselwe elivunguzayo linobubanzi obukhulu, elingafinyelela ngaphezu kuka-3000mm, futhi lifaneleka kakhulu ukuthutha amapayipi anobubanzi obukhulu kanye nezakhiwo zokwakha.

Ezintathu, ipayipi lensimbi elinomthungo oqondile

Ipayipi Elishiselwe I-Arc Elishiselwe Longitudinally Submerged, igama lesiNgisi yi-LSAW (Longitudinally Submerged Arc Welded Pipe), kanti uhlobo lwe-weld luwumthungo oqondile.Indlela ye-arc welding engaphansi kwamanzi iyasetshenziswa, futhi izingqimba zangaphakathi nangaphandle eziphindwe kabili ziyashiswa.Ugqinsi lwezindonga zepayipi lensimbi lomthungo oqondile likhulu uma kuqhathaniswa, futhi ukusetshenziswa kwalo kufana nokwepayipi lensimbi elivunguzayo.

Ngokwezinqubo ezahlukene zokwakha, amapayipi ensimbi ashiselwe ngomthungo oqondile angahlukaniswa abe izigaba ezimbili: I-UOE (Uing and Oing forming pipe) kanye ne-JCOE (J-ing, C-ing kanye ne-O-ing pipe).Indlela yokwenza i-UOE (ukwakha u-U, ukwakheka kwe-O, ukunwetshwa kobubanzi buka-E), indlela yokwenza i-JCOE (ipuleti lensimbi licindezelwa libe wumumo ongu-J, bese licindezelwa libe umumo ongu-C no-O ngokushintshana, bese liyanwetshwa).

Kumele kuqashelwe ukuthi inqubo yokushisela i-arc engaphansi kwamanzi (SAW) iwuhlobo lwe-welding kagesi ye-fusion (EFW Electric Fusion Welded Pipe), okuwukuhlanganisa izinsimbi ngokushisa insimbi phakathi kwe-electrode eyodwa noma amaningana asebenzisekayo kanye nendawo yokusebenza.Enye yezinqubo lapho i-arc incibilikisa ngokugcwele insimbi nezinto zokugcwalisa ngaphandle kwengcindezi, futhi ingxenye yensimbi yokugcwalisa ivela kuma-electrode.

Isikhathi sokuthumela: Jan-06-2023