Amapuleti ensimbi angagugi:

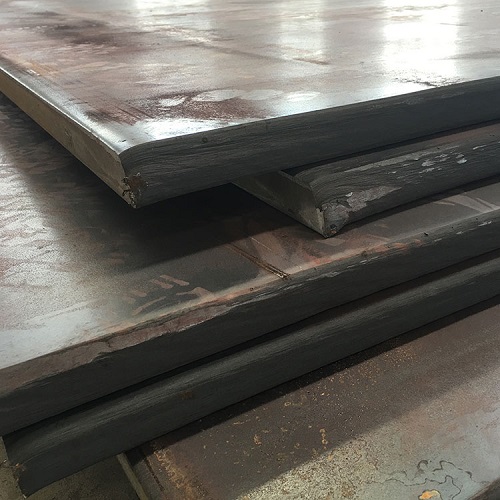

(1) I-NM360 (360 engagqoki)

Ukuqamba igama: U-N uthi ukumelana (nai) M wuhlamvu lokuqala lwe-pinyin lwezinhlamvu ezimbili zesiShayina zokugaya (mo), futhi u-360 umele ubulukhuni obujwayelekile be-Brinell balamapuleti ensimbi.

Ukwelashwa kokushisa: ukushisa okuphezulu, ukucisha + ukushisa (ukucisha kanye nokushisa)

Isicelo: Ishidi lensimbi elingagqoki le-NM360 lisetshenziswa kakhulu emishinini yezimayini, emishinini yezimayini yamalahle, ezemvelo

Ibuye isetshenziswe ngokujwayelekile njengensimbi yesakhiwo yamandla aphezulu enamandla okukhiqiza ≥ 700MPa.Ngokuyinhloko iwukunikeza ukuvikeleka ngezikhathi noma izingxenye ezidinga ukumelana nokuguga, ukuze kwenziwe okokusebenza kube nempilo ende, ukunciphisa isikhathi sokunakekela esibangelwa ukunakekelwa, futhi ngokuhambisanayo kuncishiswe ukutshalwa kwezimali kwezimali.

Ukusebenza: Isivuno singaphezu kuka-800, futhi amandla aqinile angaphezulu kuka-1000.

(2) NM400

I-NM400 iyipuleti lensimbi elinamandla angagugi.I-NM400 inamandla amakhulu kakhulu emishini;izakhiwo zayo zemishini ziphindwe izikhathi ezi-3 kuya kwezi-5 kunamashidi ensimbi aphansi-i-alloy;ingathuthukisa kakhulu ukumelana nokugqoka kwezingxenye ezihlobene nomshini;ngaleyo ndlela kuthuthukisa impilo yesevisi yemishini nokunciphisa izindleko zokukhiqiza.Ubulukhuni bobuso balo mkhiqizo ngokuvamile bufinyelela ku-360 ~ 450HB.Amapuleti ensimbi esakhiwo asebenzayo okucubungula nokukhiqizwa kwezingxenye ezingagugi nezisengozini ezimayini nemishini ehlukahlukene yokwakha.

Ishidi lensimbi elingagugi i-NM400 lisetshenziswa kabanzi emishinini yokwakha, imishini yezimayini, imishini yezimayini zamalahle, imishini yokuvikela imvelo, imishini yensimbi nezinye izingxenye zomkhiqizo.I-Excavator, isilayishi, ipuleti lebhakede le-bulldozer, i-edge plate, i-side edge plate, i-blade.Ama-crusher liners, ama-blades.

(3) Mn13 (insimbi yemanganese ephezulu)

I-Mn13 iyinsimbi ephakeme ye-manganese engagqoki (HIGH MANGANESE STELL SKRAP), okuyinketho engcono kakhulu phakathi kwezinto ezingagugi njengomthelela oqinile nokugqokwa kwempahla enomfutho ophezulu.

Kunezici ezimbili ezinkulu kakhulu zensimbi ephezulu ye-manganese: enye iwukuthi uma umthelela wangaphandle umkhulu, uyanda ukumelana nokugqokwa kongqimba lwawo olungaphezulu.Uma ithintekile, ubulukhuni bayo bobuso buzokhula ngokushesha ukusuka ku-HB200 kuye ngaphezu kwe-HB700, ngaleyo ndlela kukhiqize ungqimba lwangaphezulu olungagugi kakhulu.I-austenite kungqimba lwangaphakathi lwepuleti lensimbi isagcina ukuqina komthelela omuhle;okwesibili ukuthi ngokuguga kancane kancane kongqimba oluqinile olungaphezulu, izingqimba ezintsha eziqinisiwe zizoqhubeka zakha.

Ipuleti lensimbi eligoqiwe le-Mn13 linokumelana okuhle kakhulu nokugqokwa komthelela oqinile kanye nokugqokwa kwengcindezi ephezulu, ngeke liphuke ngesikhathi lisetshenziswa, futhi linezakhiwo ezilula zokwenza imishini njengokusika, ukushisela nokugoba.

I-chromium cast iron esetshenziswa ngokwesiko inokumelana okuhle nokugqokwa kokuguga okunyakazayo.Ipuleti lensimbi eligoqiwe elingu-Mn13 linganciphisa ngempumelelo izindleko zokugqoka izingxenye zemishini, longe izindleko zokulungisa izinto zokusebenza, futhi lithuthukise ukuncintisana kwemikhiqizo eqediwe.

Kodwa-ke, ukumelana nokugqoka kwensimbi ephezulu ye-manganese kubonisa ukuphakama kwayo kuphela ngaphansi kwezimo ezanele ukwakha ukuqina komsebenzi, futhi kumpofu kwezinye izimo.

Insimbi ejwayelekile ye-manganese engagqoki i-Mn17 iwukukhuphula inani le-manganese ngesisekelo sensimbi engu-Mn13, ethuthukisa ukuzinza kwe-austenite futhi ivimbele imvula yama-carbides, ngaleyo ndlela ithuthukise amandla nepulasitiki yensimbi futhi ithuthukise umsebenzi. ikhono lokuqina lensimbi.kanye nokumelana nemihuzuko.Isibonelo, impilo yesevisi yezimfoloko zikaloliwe i-ZGMn18 ezisetshenziswa enyakatho ingaphezulu ngo-20%~25% ngaphezu kwaleyo ye-ZGMn13.

Amabanga nobubanzi bokusetshenziswa kwensimbi ephezulu yemanganese evame ukusetshenziswa eShayina yilawa: I-ZGMn13-1 (C 1.10%~1.50%) isetshenziselwa izingxenye ezinomthelela ophansi, i-ZGMn13-2 (C1.00%~1.40%) isetshenziselwa izingxenye ezijwayelekile, i-ZGMn13- 3 (C0.90%~1.30%) isetshenziselwa izingxenye eziyinkimbinkimbi, futhi i-ZGMn13-4 (C0.90%~1.20%) isetshenziselwa izingxenye ezinomthelela ophezulu.Okuqukethwe kwe-manganese kwamabanga amane ensimbi angenhla yi-11.0% kuya ku-14.0%.

Ukuze kushiswe futhi kulungiswe, ama-electrodes asekelwe ku-manganese-nickel asekelwe ku-austenite (uhlobo D256 noma i-D266) kufanele akhethwe, ngokucaciswa okude nokuncane, φ3.2mm×350mm, futhi ukumbozwa kwangaphandle kuyi-alkaline.Indlela yokusebenza yamukela ukuxhumana kwe-DC reverse, i-current encane, i-arc ebuthakathaka, ubuhlalu obuncane bokushisela kanye nezingqimba eziningi zokushisela, futhi ihlale igcina izinga lokushisa eliphansi nokushisa okuphansi.Shaya ngenkathi ushisela ukuze uqede ukucindezeleka.Ukulingisa okubalulekile kufanele kubonakale iphutha.I-Flash welding (i-Swiss GAAS80/700 flash welding machine) noma i-MAG welding (efana ne-Nissan YD-S-500) ingasetshenziselwa ukushisela okubaluleke kakhulu, okungaqinisekisa ngempumelelo izakhiwo zemishini yokushisela.

Isithasiselo 1: Umqondo wobulukhuni

Ukuqina inkomba yokusebenza yokulinganisa ukuthamba nobulukhuni bezinto.Kunezindlela eziningi zokuhlola ubulukhuni, izimiso azifani, futhi amanani okuqina nezincazelo azifani ncamashi.Okuvame kakhulu ukuhlola ubulukhuni bendlela yokulayisha i-static, okungukuthi ukuqina kwe-Brinell (HB), ukuqina kwe-Rockwell (HRA, HRB, HRC), ukuqina kwe-Vickers (HV), ukuqina kwepulasitiki yerabha e-Shore (HA, HD) nobunye ubulukhuni Inani layo libonisa ikhono lobuso bezinto zokumelana nokungena kwento eqinile.Ukuqina akulona inani elilula lomzimba, kodwa inkomba yokusebenza okuphelele ebonisa ukunwebeka, ukuqina kwepulasitiki, amandla kanye nokuqina kwezinto.

Ukuqina kwensimbi: Igama lekhodi yobulukhuni bensimbi ngu-H. Ngokwezindlela ezihlukene zokuhlola ubulukhuni, kukhona ikakhulukazi izinkulumo ezilandelayo.

●Izinkulumo ezivamile zihlanganisa u-Brinell (HB), u-Rockwell (HRC), u-Vickers (HV), u-Leeb (HL) ubulukhuni, njll., phakathi kwawo i-HB ne-HRC evame ukusetshenziswa kakhulu.

● I-HB inohlelo olubanzi lwezinhlelo zokusebenza, futhi ngokuvamile isetshenziswa uma impahla ithambile, njengezinsimbi ezingenayo ayoni, insimbi ngaphambi kokwelashwa kokushisa noma ngemva kokuhushula.I-HRC ifanele izinto ezinokuqina okuphezulu kwendawo, njengokuqina kokwelashwa kokushisa, njll.

Umehluko phakathi kwalokhu okubili ukuthi ama-probes abahloli bokuqina ahlukile.Ama-probe e-Brinell hardness tester amabhola ensimbi, kanti ama-probe e-Rockwell hardness tester angamadayimane.Ngaphansi kwezimo ezithile, i-HB ne-HRC zingashintshaniswa ngokubheka phezulu kwetafula.Ifomula yayo yokubala ngokwengqondo ingarekhodwa cishe ngokuthi: 1HRC≈1/10HB.

●I-HV-ifanele ukuhlaziywa kwe-microscopic.I-Vickers hardness (HV) icindezelwa ebusweni bento enomthwalo ongaphansi kuka-120kg kanye ne-indenter yekhoni yesikwele sedayimane ene-vertex angle engu-136 °, futhi indawo engaphezulu yomgodi wokungeniswa wento ihlukaniswa umthwalo. value, okuyinani lobulukhuni be-Vickers (HV ).Ukuqina kwe-Rockwell (HR-) kunqunywa ukujula kwe-indentation plastic deformation ukuze kunqunywe inkomba yenani lobulukhuni.Kulula ukuyisebenzisa, iyashesha futhi inembile, futhi ifanele ukukhiqizwa ngobuningi.

Okunamathiselwe 2: Insimbi engagugi evame ukusetshenziswa

Kwasekhaya (Wugang, Xingang, Wuhan Iron and Steel, Nangang, Baosteel): NM360, NM400, NM450, NM500, NR360, NR400, B-HARD360, B-HARD400, B-HARD450

Insimbi engagqoki yaseSweden: HARDOX400, HARDOX450, HARDOX500, HARDOX600, SB-50, SB-45

Insimbi yaseJalimane ekwazi ukumelana nokugqokwa: XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500

Insimbi yaseBelgium engagqoki: QUARD400, QUARD450, QUARD500

Insimbi yaseFrance engagqoki: FORA400, FORA500, Creusabro4800, Creusabro8000

Insimbi yaseFinnish engagugi: RAEX400, RAEX450, RAEX500

Insimbi yaseJapan engagqoki: JFE-EH360, JFE-EH400, JFE-EH500, WEL-HARD400, WEL-HARD500.

Isikhathi sokuthumela: Jan-29-2023